Real potential for value creation: assembly technology

14 June 2022 , Dr. Uwe Bolz

Assembly work is what the SHK installer predominantly carries out on site. Sales talks, contract negotiations, product selection, planning and orders have then already been completed and should provide the basis for a successful construction project. As a result, organization and installation techniques become the most important factors in the project execution phase. They determine whether the expected profit can be realized - or whether the construction site will incur losses.

It therefore makes absolute sense for every company to take a critical look at individual processes or subsections again and again and from different perspectives, and to optimize them if necessary. This is what is to be done here for pipeline assembly.

Mounting rails vs. individual suspensions

In larger residential buildings, and even more so in industrial and commercial facilities, the use of mounting rails for pipeline installation has become indispensable. In case of single-family homes and buildings with a small number of residential units, single suspensions are also increasingly being used.

In case of a single pipe, this is probably also the method of choice, but if two or more pipes run parallel under the ceiling, then the question arises whether a mounting rail is not more sensible here than individual suspension. And indeed, there are criteria that answer this question.

When it comes to money...

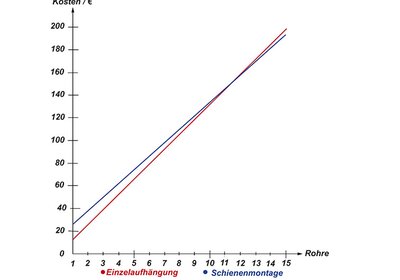

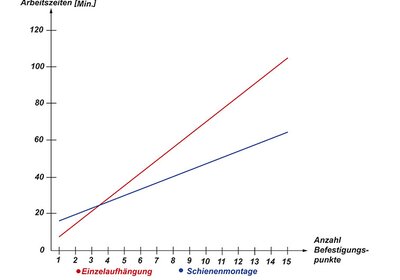

Let's start with the costs for material and working time. For this purpose, Volker Weber, Head of Product Management, has drawn up a diagram for a comparison of assembly times and material costs. The list prices were used for the material.

The operations required to suspend a single pipe are drilling, placing a dowel, screwing in a threaded rod, countering and mounting a pipe clamp. The alternative to this is rails, each of which is fixed in the ceiling with two dowels. Once the rail is suspended, the individual pipes can each be fastened with much less effort - especially if the installer uses rapid assembly systems. So from a certain number of pipes, rail mounting is definitely more cost-effective, because the saved working time becomes more and more important.

Many steps are the same for both assembly variants. It is therefore sufficient for a comparison to consider only those steps where the work differs. Therefore, the provision of the tools and parts required for the assembly and the cleaning up of the workplace afterwards, for example, should not be taken into account.

For a single suspension, the following variable quantities must be taken into account in the time required:

- Set ladder per hole (1 min),

- Marking the hole and drilling (2 min),

- Set dowel (1 min),

- Screw in threaded rod and lock (2 min),

- Screw on pipe clamp (1 min).

In case of ceiling rail installation for a single pipe clamp, the effort for setting up the ladder and drilling is, of course, doubled (6 min). Sawing the rail to size is added (3 min) and the rail is fixed to the ceiling with two dowels (3 min).

For the model calculation, the Stex 35 quick mounting system from MEFA is chosen: For this lightweight system, half a minute of assembly time is rather generous. For conventional fastening systems, a longer time is usually required. The time required for screwing in and countering the threaded rod and screwing on the pipe clamp is the same for both methods (3 min). Except for the hourly rate, all the conditions for a comparison have now been established.

Comparison costs for individual suspensions and rail installation can now be plotted as a straight line over the number of pipes in a diagram. For an hourly rate of 60 euros, the straight lines intersect between 11 and 12 pipes. However, the angle between these straight lines is flat. This means that the result is very sensitive to changes in the parameters, which - as I said - consist of assumptions. Thus, the comparative calculation specifies an accuracy that does not exist in practice.

Thus, the pure cost comparison does not provide reliable results. Rather, it can be stated that the number of pipelines has a subordinate relevance for the decision whether single or rail installation is more sensible.

There are other criteria that are much more relevant for the decision whether rail or single suspension is to be preferred.

Protecting the labor factor: A whole bundle of criteria can be summarized under the umbrella term "protecting the labor factor." In times of shortage of skilled labor, this is of central importance for our entire industry. In the case of pipeline installation, the points that speak in favor of rail installation would be revisability in the event of subsequent change requests or possible installation errors, expandability even beyond the trade, time savings and, last but not least, the aesthetics of the installation.

Revisionability: On which construction site are there no changes or errors? With rail installation, piping can be corrected with little effort and without additional holes in the ceiling.

Expandability: The building services upgrade through automation and new energy sources is in full swing. With a generous rail design, additional lines can be quickly installed, such as brine lines for solar collectors, compressed air lines for commercial operations, and cable trays. In the process, perhaps even another installation level can be introduced if necessary, because if several insulated pipes run parallel to each other with a small distance between them, things get tight. By hanging more rails underneath, additional piping can be placed at a different height.

Time savings: skilled labor is the limiting factor in construction. Rail installation saves considerable time and increases earning power - especially when using one of the relevant rapid installation techniques. For the parameters of the differential cost comparison above, the second graph shows the pure assembly times. Here, the intersection point from which the assembly times are more favorable is already at just over three pipelines. In the case of rail installation, therefore, the increased material input means that working time can be saved to a considerable extent even with a relatively small number of pipelines.

Aesthetics: A good craftsman wants to be proud of his work. If a pipe hangs a little crooked in the room, correcting it with individual suspension is time-consuming and also leaves an unsightly hole in the ceiling. With tracks, the pipe runs can be corrected with little effort, or the screws are not tightened until all the pipes are hanging correctly. This applies even more in areas with public traffic and when increased demands are placed on the architecture.

Conclusion: A rule of thumb such as: "From X pipes, rail mounting should be preferred" makes little sense. Rather, the question arises whether a mounting rail is not the better solution from as few as two pipelines. The arguments in the sections on revisability, expandability, time savings and aesthetics suggest this conclusion.